DEGREES IN CNC and Advanced Machining

CNC and Advanced Machining Associate of Applied Science

By the Numbers

CNC and Advanced Machining Diploma

By the Numbers

Why Choose This Program

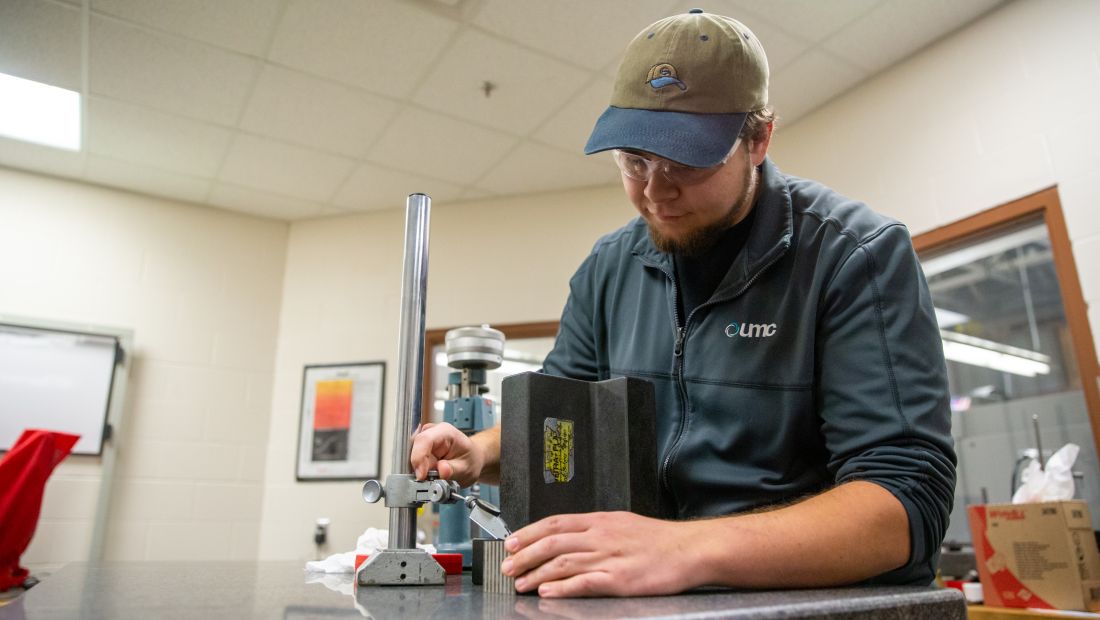

Our students gain skills to read blueprints and written instructions to convert various materials in intricate, precise, usable parts.

At SCTCC, we’ve designed our program to benefit every student who joins our program. We give students real-world experience in the classroom so they can be certain to impress any future employer.

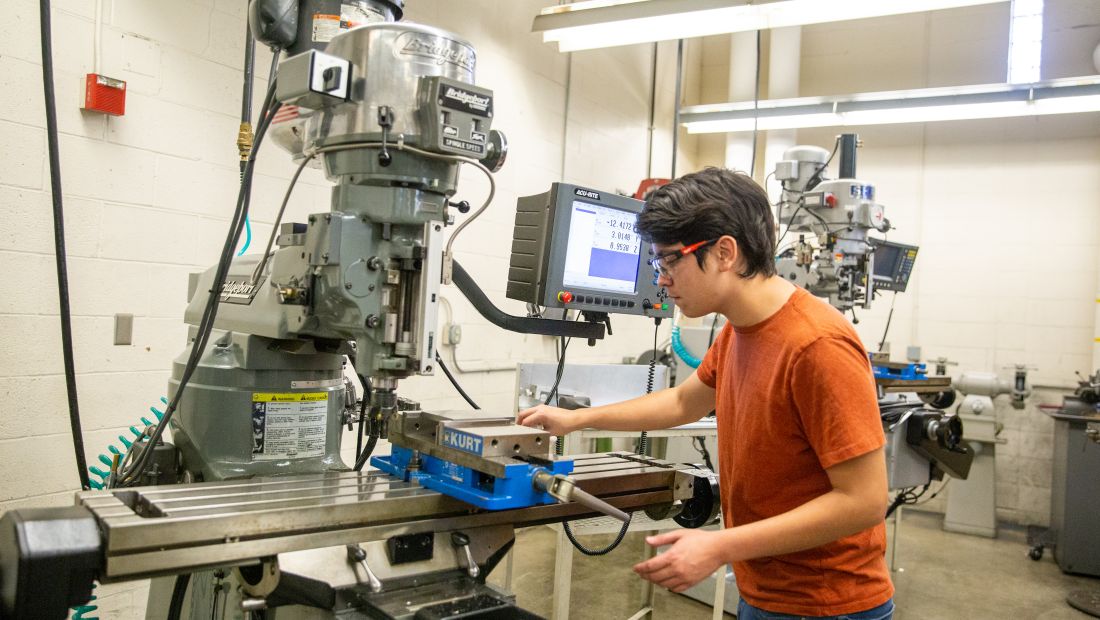

By using machine tools such as lathes, mills, grinders, drill-presses, computers, and CNC machines, graduates from our program are ready for the expanding workforce as a machine operator, machinist, or tool and die or mold-maker apprentice.

Placement rate from self-reported data of graduates available for work in field of study up to one year post graduation. Wage data is from Minnesota Dept. of Employment and Economic Development (DEED).

From Degree to Career

When you choose the CNC and Advanced Machining program at SCTCC, you'll gain skills that will directly transfer to the workplace. With your degree, you can build your career as a machinist, toolmaker, moldmaker, CNC operator, or quality inspector, to name a few options.

Our CNC and Advanced Machining program prides itself in equipping every student with the tools needed to succeed in the workforce. Graduates from our program can demonstrate problem-solving abilities, read blueprints and written instructions, and select proper machinery, materials, and tools.

After graduation students have proficiencies with machine tools like lathes, mills, grinders, drill-presses, computers, and CNC machines. We even teach our students the setup and milling operations on Bridgeports, the setup and turning operations on Lathes, and G & M code programming for CNC machines.

With a degree from our CNC and Advanced Machining program, graduates can utilize CAM designing and programming software, CNC setup and operation, and multi-axis CNC Machining and Turning center programming, setup, and operation.

While attending SCTCC, students are required to attend tool shows and metalworking exhibitions when possible and read trade journals and magazines for professional growth.

Quick Glance

- Demonstrates problem-solving ability

- Attends tool shows and metalworking exhibitions when possible

- Reads trade journals and magazines for professional growth

- Read blueprints and written instructions

- Select proper machinery, materials, and tools

- Gain proficiency with machine tools such as lathes, mills, grinders, drill-presses, computers, and computerized numerical control (CNC) machines

- Setup and milling operations on Bridgeports

- Setup and turning operations on Lathes

- G & M code programming for CNC machines

- CAM designing and programming software

- CNC setup and operation

- Multi-axis CNC Machining and Turning center programming/setup and operation

View all program learner outcomes

Types of Careers

Graduates from our CNC and Advanced Machining program have a variety of opportunities in the workforce. Our students have found employment opportunities as manual and CNC machinists, toolmakers, mold-makers, quality inspectors, and much more.

You can even find SCTCC graduates using their skills working with CNC operators, setup, and programming. With so many ways to use your degree, every student is certain to find a career path right for them.

A day in the life of an SCTCC graduate is utilizing skills taught in our classrooms like problem-solving and using precision with tools while working as a CNC machinist.

Quick Glance

- Machinist: Manual and CNC

- Toolmaker

- Moldmaker

- CNC Operator

- CNC Setup

- CNC programming

- Quality inspector

At SCTCC, we don’t only prepare students for their future careers, but also for future academic endeavors. All of the SCTCC general education courses are a part of the Minnesota Transfer Curriculum. Students can continue their studies at Bemidji State University or Minnesota State University, Moorhead to benefit from our 2 + 2 articulation.

Ready to Take the Next Step?

Are you ready to learn more about the CNC and Advanced Machining program and being a student at SCTCC? Visit SCTCC for a tour or an information session.

Connect with the SCTCC Admissions team:

- Call us at 320-308-5089

-

Email us at recruitment@sctcc.edu

- On campus Monday-Friday, 8 a.m.-4:30 p.m.

Fill out this form to receive useful information.

Visit SCTCC

Want to know more about SCTCC?

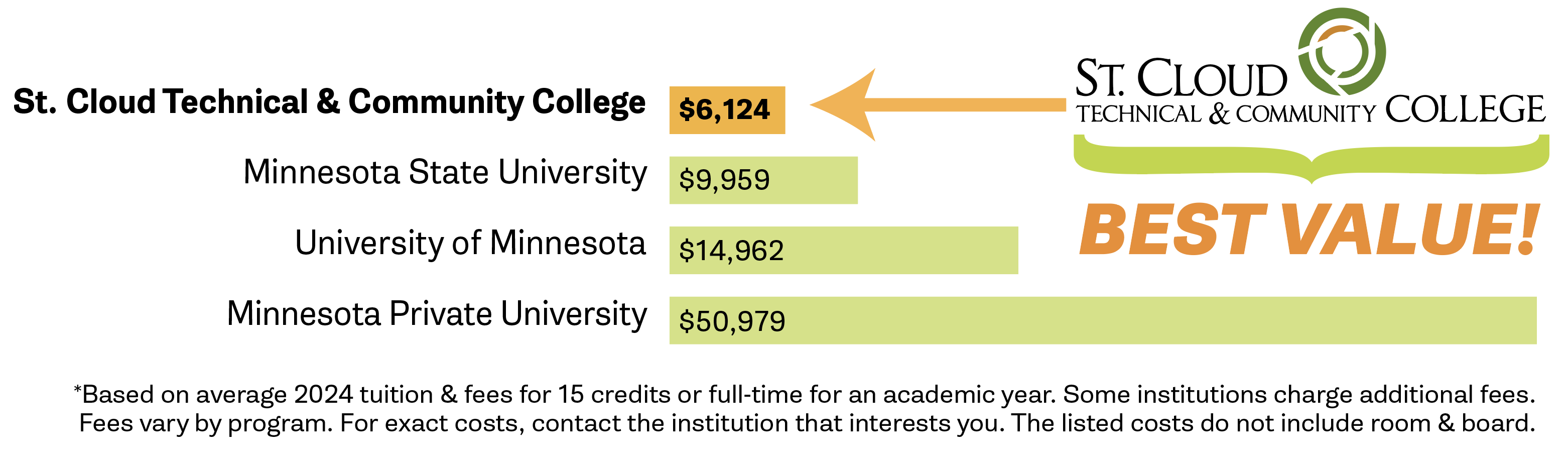

Paying for College

Students choose SCTCC for a lot of reasons, but saving money is one reason we hear from almost every student at SCTCC. We’ve got a breakdown of the costs for the program, along with information on financial aid and scholarships.

Program Info for Current Students

As a CNC and Advanced Machining major, students can join the student group, SkillsUSA. SkillsUSA is a partnership of students, teachers, and industries working together to ensure America has a skilled workforce. SkillsUSA helps students excel and provides educational programs, events, and competitions that support career and technical education (CTE) in the nation’s classrooms.

CNC and Advanced Machining Instructor

Good Stuff

SCTCC Celebrates: Advanced Manufacturing Center, 75th Anniversary, Cyclones Volleyball

SCTCC Celebrates Groundbreaking for Advanced Manufacturing Lab